🔧 Transform your garage into a powerhouse of style and durability—no sweat, all swagger!

GarageTrac Diamond is a premium, durable interlocking garage flooring tile set made from high-impact copolymer. Designed for quick, tool-free installation, it supports rolling loads over 40,000 lbs and features a patented diamond tread pattern for slip resistance. Its stain-resistant, washable surface and modular design offer endless customization options, making it the ultimate upgrade for any professional-grade garage or workspace.

| ASIN | B0753MZ79K |

| Best Sellers Rank | #393,627 in Home Improvement ( See Top 100 in Home Improvement ) #148 in Decking |

| Brand | Big Floors |

| Capacity | 12 Pack |

| Color | Alloy |

| Colour | Alloy |

| Customer Reviews | 4.5 4.5 out of 5 stars (1,227) |

| Date First Available | 22 September 2017 |

| Edge Style | Square Edge |

| Finish Type | Polished |

| Form Factor | Diamond |

| Generic Name | Durable Interlocking Modular Garage Flooring Tile |

| Global Trade Identification Number | 00857703005845 |

| Installation Type | Interlocking |

| Item Model Number | G90012ALLY |

| Item Part Number | G90012ALLY |

| Item Weight | 386 g |

| Manufacturer | SnapLock Industries |

| Material | Copolymer |

| Net Quantity | 12.0 Square Feet |

| Pattern | Diamond |

| Primary material | Copolymer |

| Product Dimensions | 30.5L x 0.1W Centimeters |

| Recommended Uses For Product | Garage, Workshop, Tool Shed, Basement, Show Room, Display Floor |

| Shape | Diamond |

| Shipping Weight | 4.86 Kilograms |

| Size | 12 Pack |

| Special Feature | Moisture Resistant, Slip Resistant, Stain Resistant, Washable |

| Style | Modern |

| UPC | 857703005845 |

| Water Resistance Level | Moisture Resistant |

| What is in the box? | GarageTrac Diamond Interlocking Modular Garage Flooring Tile (12) |

M**H

Easy installation and durability, look and quality of product.

P**G

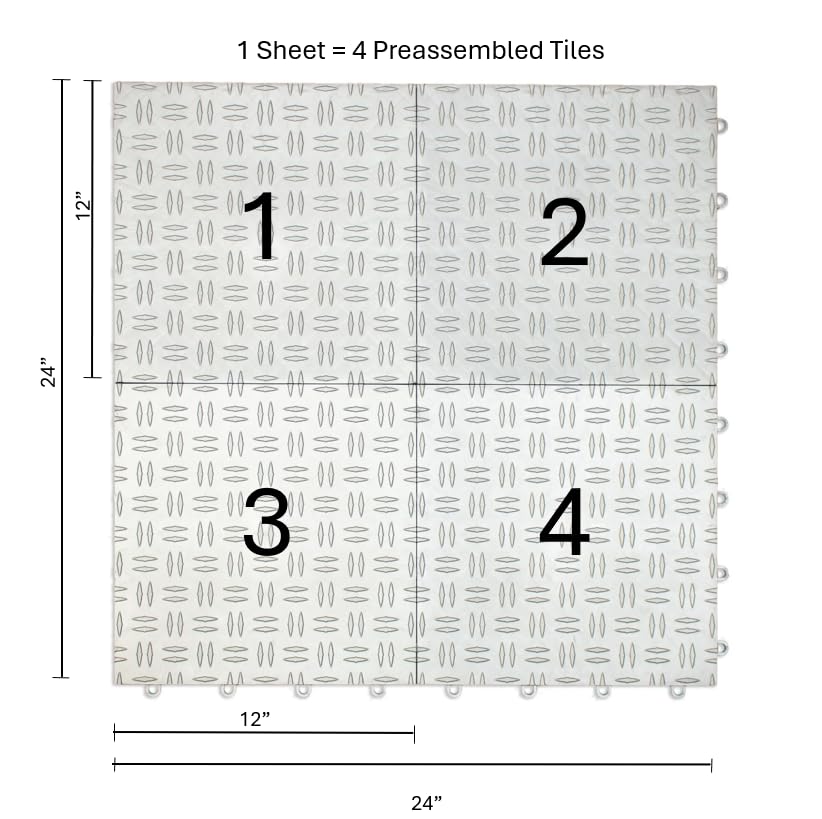

The 25-year-old concrete garage floor in the house I purchased had small cracks, paint and oil stains, a few scratches and peeling paint in some area. The more I looked into repairing and repainting the floor, the more I learned about how difficult and expensive this can be. And then I heard horror stories about even the best epoxy coatings showing tire tracks on hot days or even peeling if the surface preparation was not perfect. My prior house had come with this GarageTrac floor garage covering, and for the 11 years I lived in that house it remained perfect - even under my 4,500 lb SUV. So I decided to go that way again in the new house. Installation is very easy if you have the right tools - a hired helper and I got it done in about 6 hrs. Most of the job gets done very quickly; the edging takes more steps. You select a starting spot and begin snapping the tiles together. My packages came in 2 ft. x 2 ft sections of 4 tiles already assembled. No surface prep is needed at all. Just sweep off loose dirt, and knock off anything that protrudes from the surface. Cracks and peeling paint do not need anything done. Now to some tips on installing this floor: 1.) Where you start is VERY important. While the material is sitting loosely on the garage floor, it is too heavy to move a big section later on. You want the front edge to be just inside the garage door, with just a small gap. The door needs to close onto the actual garage door, not onto this material. You could just place the edge of a tile right there, but it is better to add these items first (sold separatly: https://www.amazon.com/gp/product/B0755MNVZ9/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1 The floor material in not too think, but you really need these little ramp pieces to make a smooth transition up to the finished floor level. The tiles themselves have exposed "loops" on 2 edges and hidden pegs that go into those loops on 2 edges. You also need to start with a full tile a short distance (leave 1/4" for expansion) either left or right. The best way to accomplish all of this is to first lay a big "L" - a row of tiles about halfway across the front of the garage, exactly parallel to the opening, with the sloped edges attached, in the right depth so the door closes OK. The other part of the "L" runs from front to back. From that front-to-back portion, snap on a series of tiles until a full tile reaches to a point that is 1/4" from a main side wall. (My garage has steps on one side and intruding cabinets on the other, so I needed top find this spot about 1/3 of the way back.) Remember: these tiles have those protruding loops on 2 edges. Orient the tile so that one edge properly engages the sloped garage-front edging. And you want the edge extending to a side wall to be smooth, without the protruding loops. 2.) Attaching tiles The fit between tiles is very tight. The manufacturer suggest that you stomp the pegs into the loops to attach them. But this is very hard on the feet after a while. For most of them, I used a heavy rubber mallet to tap them together. Since two of us were working on the floor, my partner also did fine with a conventional hammer on a block of wood. These tiles are very tough, but don't hit them directly with a metal hammer. 3.) Separating tiles Once tiles are attached to each other, they really don't want to come apart. But you need to separate some of those 2 x 2 squares to get single tiles, and sometimes you'll make a mistake when laying the floor. The only way I have found to separate them is to place a piece of 2 x 4 under the UP side of a pair that need to come apart, and then hammer down hard through a wood block on the other side of the joint. You'll be afraid of breaking the tile (you won't), but it takes a lot of force. 4.) Finishing the starting rows of tiles. It will take you a while and some careful measuring to get these starting tiles in just the right alignment, but it is the most important step in the whole job. Next, add a few more rows of tile along the inside of the "L" along the front and front-to-back section. This makes the whole assembly more stiff, so you can make absolutely sure everything is dead straight and constant distance from front and side. But it won't be. No garage or room of any kind is perfectly square. We'll get to dealing with this. 5.) Laying the body of the floor. This is the easiest part. Just tap into place all of the 2x2 sections you can and then separate ed 1x2 and 1x1 pieces until all possible full tiles have been laid. Now give yourself a break - you are half done. 6.) All the rest of the tiles will require some cutting. The very best way to do this is with a table saw. For each partial tile, carefully measure the distance from the last full tile to the wall, subtract 1/4" and set your rip fence accordingly. On some tiles, you'll need to keep the side having the loops, so you need to compensate for those when the cut requires running those exposed loops along the fence. As with any cutting operation, cut the largest pieces first, so if you make a mistake you can reuse those scraps for smaller pieces. In my garage, I also needed to use a jig saw for small cuts around a pipe and the side tracks for my garage door. My total cost for materials and my helper worked out to just about the same as if I had an epoxy floor covering done. But based upon my prior experience, this floor will last at least a decade - probably longer - and no painted floor can claim that. If I somehow manage to damage one or more floor tiles, they can be replaced. One more tip: We keep our garage rather clean, but we cannot prevent the cars from dripping liquids. So I placed a pair of inexpensive 4' x 6' rubber-edge mats under the front of each car to catch that mess. When they get dirty enough, I drag the mats out to the driveway and hose them off.

T**N

Looks great, went together easily, took about 3 1/2 hrs. to install 400 sq.ft. Soft rubber mallet is much easier than stamping on them with your foot.

J**.

Shipping was a joke , arrived and all down one side all the hoops were broken off . They don’t ship them with any protection and the two boxes Of 96 tiles were damaged junk ... hard plastic cheap quality . Do not buy

T**N

Looks great and was easy to install, 440 sq ft garage in under 3 hrs. Easy to keep clean too.