🚀 Fill with Confidence: Elevate Your Production Game!

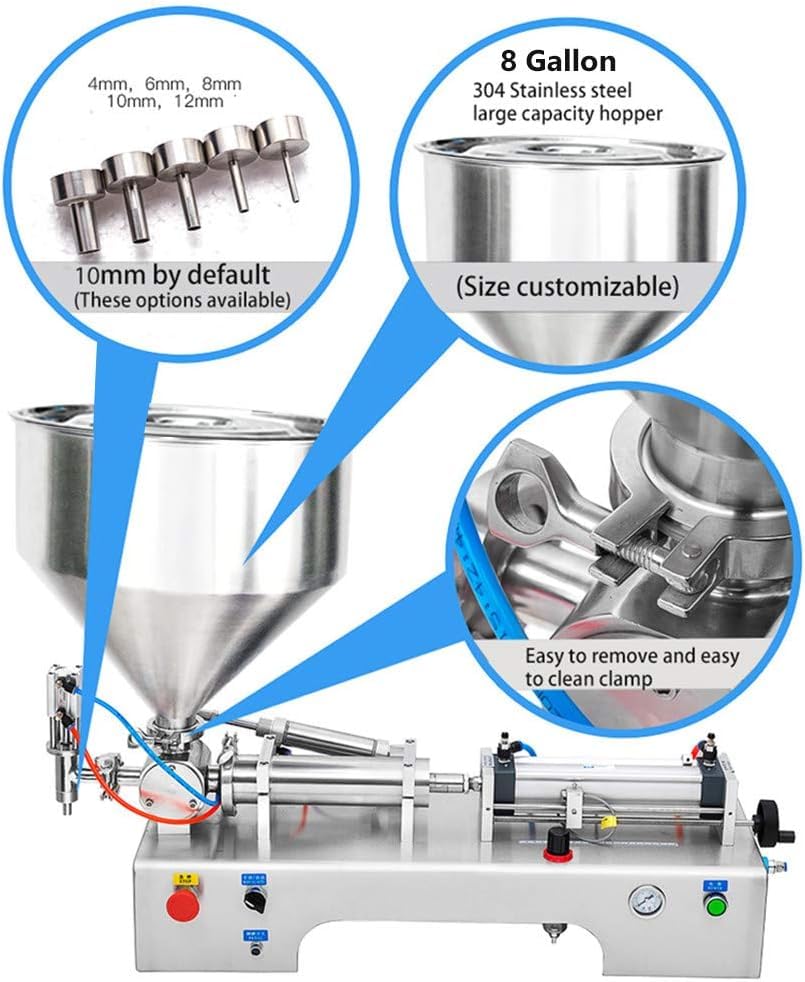

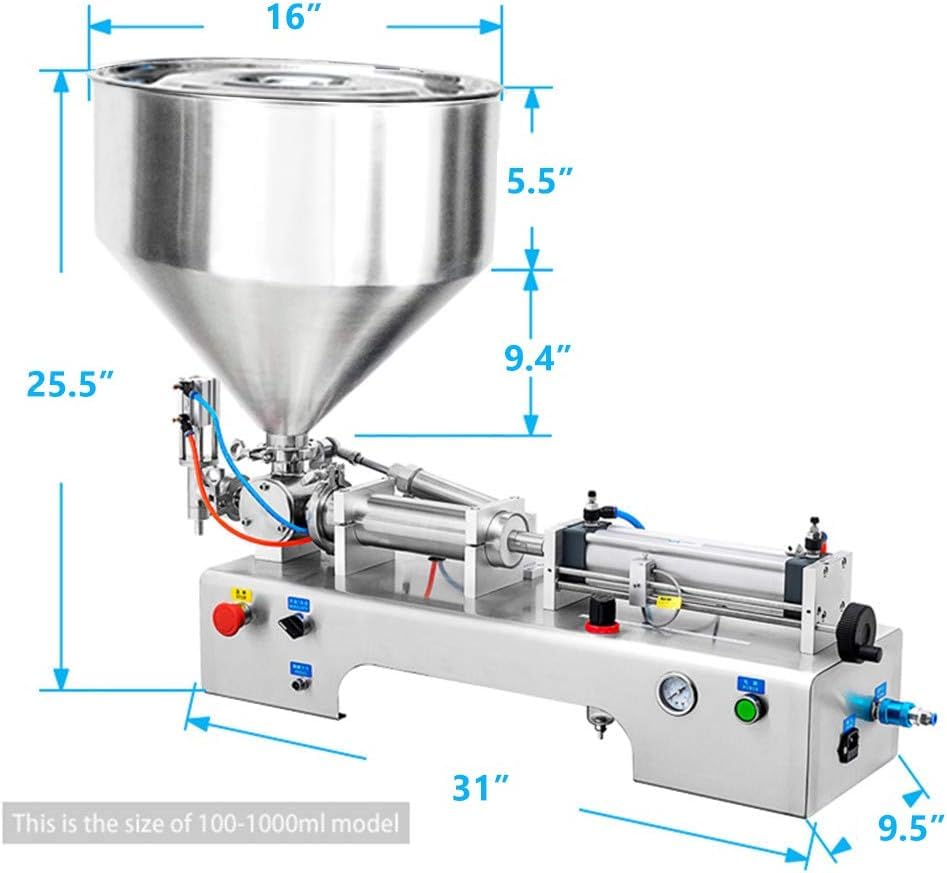

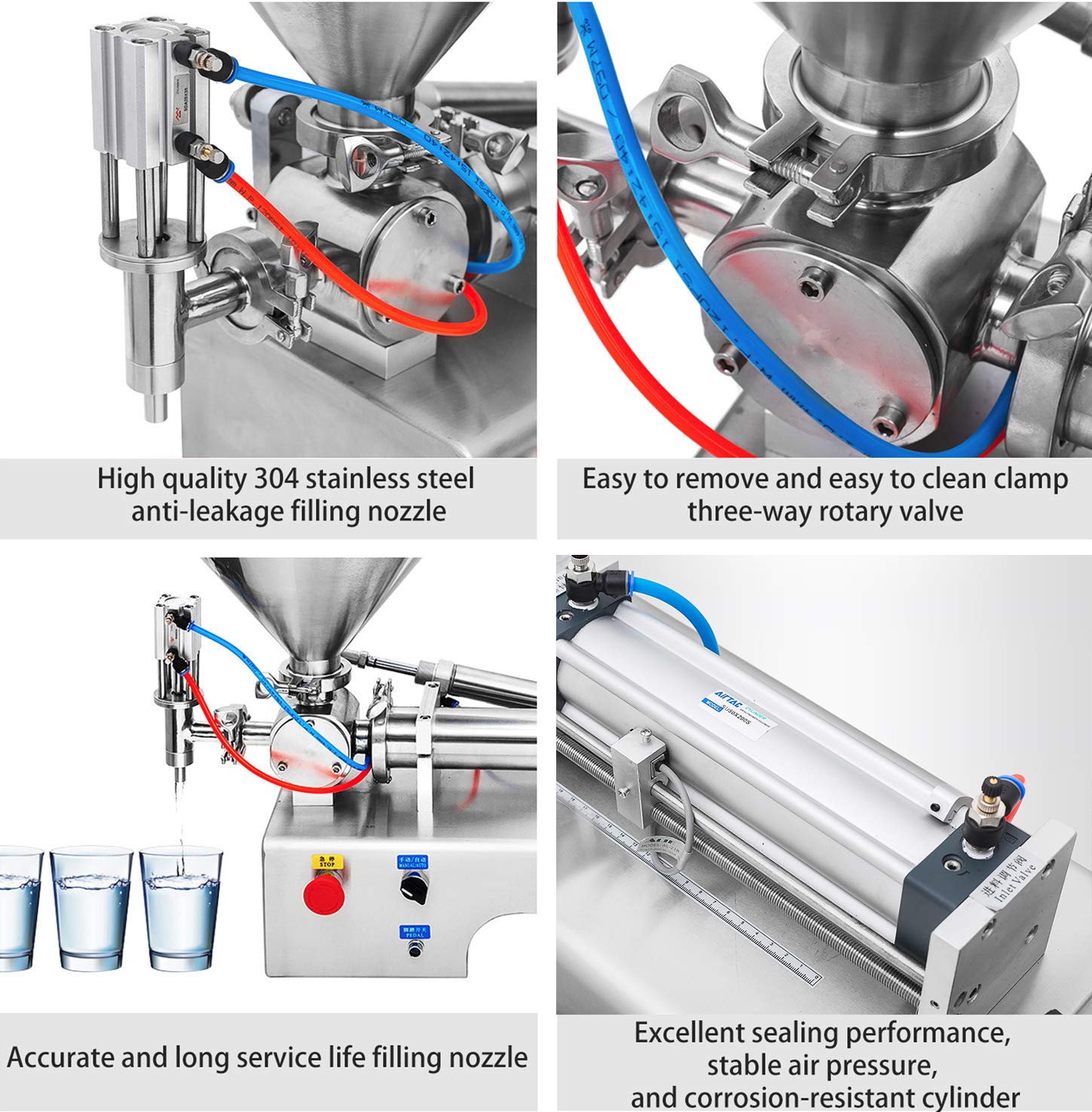

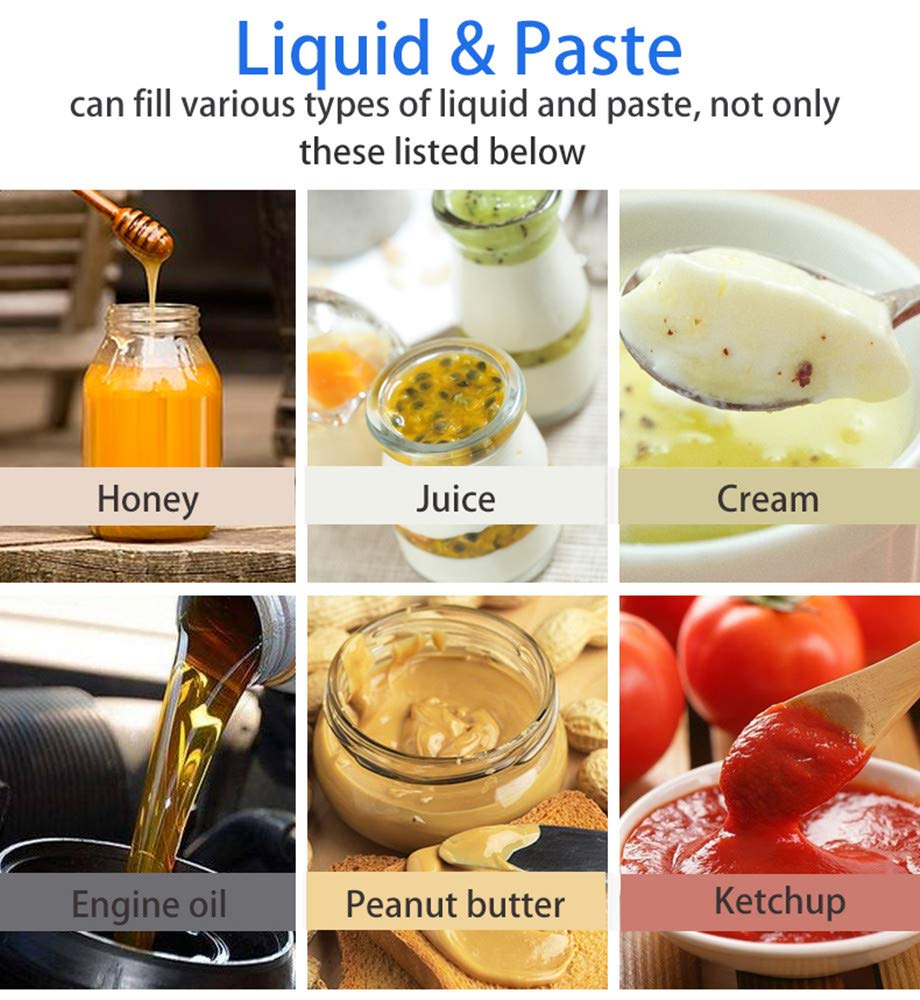

The Hanchen Liquid and Paste Filling Machine is a semi-automatic pneumatic piston filler designed for precision and versatility. With a filling capacity of 50-500ml and a speed of 5-50 bottles per minute, it caters to various industries including pharmaceuticals, cosmetics, and food. Made from high-quality materials, it ensures durability and reliability, making it an essential tool for any production line.

D**R

We are ordering a 2nd unit at 30ml-300ml

We were skeptical at first about ordering a filling machine at 10ml-100ml with an 8-gallon hopper from China. Our other option was a US version of the same thing for 4X the money. We have staff with mechanical abilities, we looked into the parts, and most are interchangeable with the USA filling machines. We could buy 4 China units for the price of one USA Unit. So that is what we are doing.The customer service has been excellent. The only negative is, you will wait a while. It took us four weeks for the unit to be built then six weeks for shipping. At first, we thought the unit had problems; it did not fill. We emailed customer service to describe the problem, and Kristy helped us out; it was the air pressure settings. The air pressure must be correct; some microvalves need adjustment for each fill size.Once you get it set up for your product size and run, we can make 350-400 2oz cream jars per hour with two people, one to fill and one to screw on the cap and box the jar. So we could do a 2,000 2oz cream jar run in about 5-6 hours with two people. We have a 1oz 30ml serum bottle that would increase production quantity by 30%-40%.Now that I know this is a high-quality filling machine with industry-standard components, we feel like we made the right choice. Every 2oz jar we made was within +/- 0.10% of the correct weight, its very accurate.We would recommend this unit, the cost for the USA-made units are not realistic. This unit came with a lid for the hopper, and a stainless-steel lid. For the USA-made version, they wanted $119 just for the lid. This showed the extreme price difference. Once your cost is 400% more for what is considered the best, I no longer want the best, I would rather have 3 of these units, and I see no real difference with them, they just cost a lot less.My Addition Review al is 5 Stars after 18 months with this filler. -Here is the math-It has been 18 months since we first started using this Hanchen Filler from 10ml-100ml.Like most people, I just thought I had to buy an America filler from Ohio and I did, years ago, for $5600, 280% more than the Hanchin Filler.Is the American filler from Ohio better, is the service better or worth it?Maybe its 5% better, but I can buy 3 Hanchin units for about the same price, with the same pistons, and parts. What amazed me is this filler came with a stainless steel lid for the hopper. The American filler was $119 extra for a hopper cover. Sure I would rather buy American if it was 10%-20% more, not 3x more, I have to think about my family's profits before others.This is not like buying a car at the same price, and there is a huge price difference that makes no sense at all.We average 5,000-10,000 30 ml and 60 ml creams like peanut butter and heavy gell bottles a month and not one problem with this filler. Just keep the screws tight, lubes, and let it run. It's solid.Production numbers & MathOne person fills two units every 5-7 seconds, about 1,000-1200 units per hour. We have a second person to put on the caps, and a 3rd to box. Thats 3 people at $16ph, I won't pay anyone under $16 per hour. It costs me about $50 in labor to fill 1,100 1oz-2oz units. If I push them hard for 3 hours, we get 3,300 units, at $150+$50 bonus for pushing 3 workers hard for 3 hours.Thats 3,300 units at $200 labor, including a $50 good job bonus divided by 3 workers.My calculations are $0.06 cents to fill a 1oz-2oz heavy cream product.I could increase efficiency by 35% if I was filling a liquid product.I am going to buy my second machine without any hesitation. I email the same person, and they have great customer service, from an office in the USA. You need someone with some ability with calibration, testing until the fill is just right, and Allen wrenches to tighten.To clean: I run hot water through the hopper 5 gallons 2 times, then remove and clean the hopper in a large sink. Then I run hot water through the clean hopper one last time until it comes out as clear water.Then I add the new product, calibrate if changing the fill amount, and you are ready.If you need to fill from 0.50 Ounces to 10 ounces, these machines are the best. If you question quality, buy two, but the parts are the same as the filler units from Ohio