🖤 Flex your creativity with Overture TPU – where durability meets seamless style!

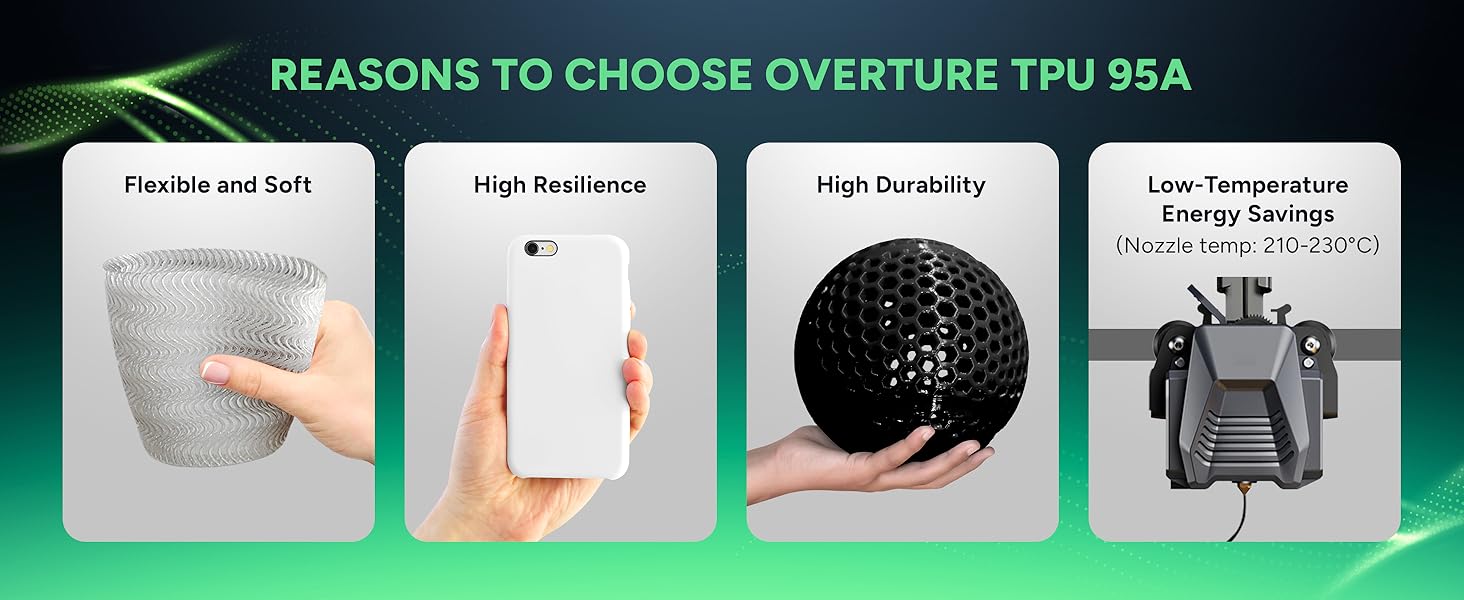

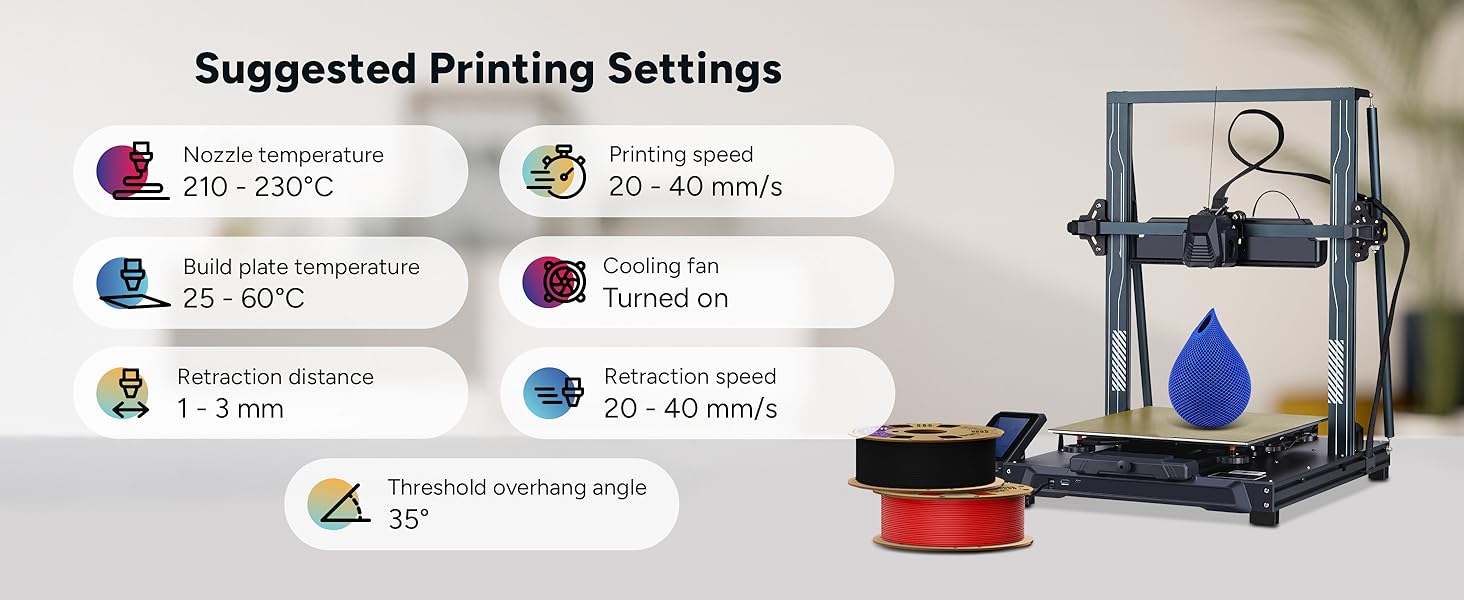

OVERTURE TPU Filament 1.75mm is a premium flexible 3D printing material with a Shore hardness of 95A, designed for superior flexibility and durability. It features excellent layer adhesion for smooth finishes, a patented clog-free formula for reliable printing, and comes vacuum-sealed to maintain quality. Compatible with most FDM printers and backed by a lifetime satisfaction guarantee, it’s ideal for flexible, high-performance projects.

| Manufacturer | OVERTURE |

| Brand | OVERTURE |

| Item Weight | 2.2 pounds |

| Product Dimensions | 8.78 x 2.95 x 8.23 inches |

| Item model number | OVTPU175 |

| Color | 1kg Tpu Black |

| Material Type | Thermoplastic Polyurethane,Aliuminum |

| Number of Items | 1 |

| Manufacturer Part Number | OVTPU175 |

Trustpilot

1 week ago

1 day ago